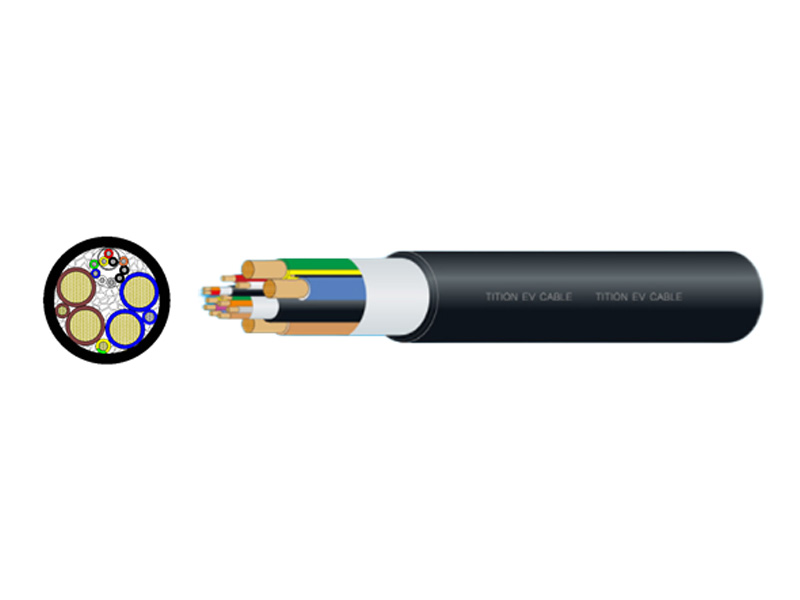

Product construction

Conductor:Bare copper

Insulation:XLPE,TPE

Filler:PP rope

Tape:Non-woven

Sheath:TPE,TPU

Features

Rating temperature:-40℃~90℃/105℃/125℃;

Rated voltage:DC 1000V; DC 1500V

Compatibility test: According to IEC 62893 or GB/T 33594;

Weather/UV Resistance test: IEC 62893 or GB/T 33594;

Impact test: According to IEC 62893 or GB/T 33594;

Crush test: According to IEC 62893 or GB/T 33594;

Bengding test: According to IEC 62893 or GB/T 33594;

scrape abrasion test: According to IEC 62893 or GB/T 33594;

Flame test: According to IEC 60332-1-2;

Resistance against chemicals: According to IEC 62893 or GB/T 33594;

Min.bending radius:6D;

Environmental requirement:RoHS & REACH;

Reference standard:GB/T 33594、UL 62、UL 2263、EN 50620、TUV 2 PFG 1908、DEKRA-175、IEC 62893

Product parameters

| Product classification | Specification mm2 | Nom.Dia. mm | mΩ/m at.20℃ | Ref.A | |

Charging cables for electric vehicles(DC): EVDC-(R)S90S90, EVDC-(R)EYS90, EVDC-(R)EYU, 62893 IEC 126 | 2X2.5+1×6+2×1.5~6+0.5~2.5(P/P2)(4~14芯) | 18.5 | 7.98 | 20 | |

| 2X4+1×6+2×1.5~6+0.5~2.5(P/P2)(4~14芯) | 18.5 | 4.95 | 30 | ||

| 2X6+1×6+2×1.5~6+0.5~2.5(P/P2)(4~14芯) | 22.0 | 3.30 | 38 | ||

| 2X10+1×6~10+2×1.5~6+0.5~2.5(P/P2)(4~14芯) | 24.5 | 1.91 | 54 | ||

| 2X16+1×6~16+2×1.5~6+0.5~2.5(P/P2)(4~14芯) | 26.0 | 1.21 | 71 | ||

| 2X20+1×6~16+2×1.5~6+0.5~2.5(P/P2)(4~14芯) | 30.0 | 0.968 | 82 | ||

| 2X25+1×6~25+2×1.5~6+0.5~2.5(P/P2)(4~14芯) | 32.0 | 0.78 | 100 | ||

| 2X35+1×6~35+2×1.5~6+0.5~2.5(P/P2)(4~14芯) | 36.0 | 0.554 | 125 | ||

| 2X40+1×6~35+2×1.5~6+0.5~2.5(P/P2)(4~14芯) | 36.5 | 0.476 | 135 | ||

| 2X50+1×6~35+2×1.5~6+0.5~2.5(P/P2)(4~14芯) | 37.0 | 0.386 | 150 | ||

| 2X70+1×6~35+2×1.5~6+0.5~2.5(P/P2)(4~14芯) | 40.0 | 0.272 | 200 | ||

| 2X80+1×6~35+2×1.5~6+0.5~2.5(P/P2)(4~14芯) | 42.0 | 0.238 | 250 | ||

| 2X95+1×6~35+2×1.5~6+0.5~2.5(P/P2)(4~14芯) | 44.0 | 0.206 | 300 | ||

| 2X120+1×6~35+2×1.5~6+0.5~2.5(P/P2)(4~14芯) | 47.0 | 0.161 | 350 | ||

| 4X2.5+1×6+2×1.5~6+0.5~2.5(P/P2)(4~14芯) | 20.0 | 7.98 | 38 | ||

| 4X4+1×6+2×1.5~6+0.5~2.5(P/P2)(4~14芯) | 22.0 | 4.95 | 54 | ||

| 4X6+1×6+2×1.5~6+0.5~2.5(P/P2)(4~14芯) | 24.0 | 3.30 | 70 | ||

| 4X10+1×6~10+2×1.5~6+0.5~2.5(P/P2)(4~14芯) | 25.0 | 1.91 | 90 | ||

| 4X16+1×6~16+2×1.5~6+0.5~2.5(P/P2)(4~14芯) | 27.0 | 1.21 | 125 | ||

| 4X20+1×6~16+2×1.5~6+0.5~2.5(P/P2)(4~14芯) | 28.5 | 0.968 | 140 | ||

| 4X25+1×6~25+2×1.5~6+0.5~2.5(P/P2)(4~14芯) | 29.0 | 0.78 | 175 | ||

| 4X35+1×6~35+2×1.5~6+0.5~2.5(P/P2)(4~14芯) | 30.0 | 0.554 | 250 | ||

| 4X40+1×6~35+2×1.5~6+0.5~2.5(P/P2)(4~14芯) | 34.0 | 0.476 | 300 | ||

| 4X50+1×6~35+2×1.5~6+0.5~2.5(P/P2)(4~14芯) | 37.0 | 0.386 | 400 | ||

Cable service environment

The warehous where cables are stored must not contain harmful gases that damage the insulation/sheath and corrode metals.During normal use,it is strictly fobidden to come into contact with acids,alkalis and mineral oils,and avoid using them in the open or exposed environment and under temperature conditions that do not meet the requirements of the wire and cable standards.

Notes

The specifications,dimensions,and structure of the above products may be changed due to technological progress.Similar specifications can be designed and manufactured according to customer needs.